At that time, I drew three-sides-picture on a piece of graph paper by calculated

size from data.

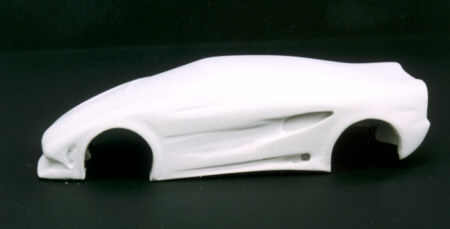

With this picture and photo, I made body of model by clay and light board.

With translating English and Italian data to Japanese, it is important

to understand history of mobile.

It is impossible to make goody not to like.

I measured base of wheels with a tape measure in Italian museum, and I

checked a color with chart of colors.

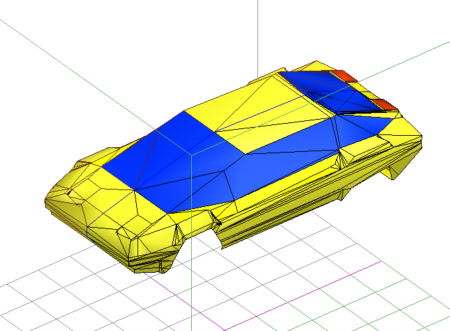

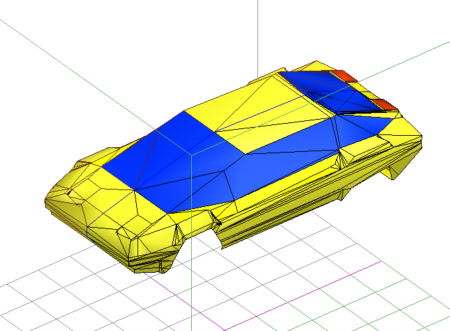

Well, at present time, it gets freely to change size and ratio of lengthwise

and crosswise with taking a few pictures into personal computer to change

solid data.

And also communication with model lovers is important to maintain passion.

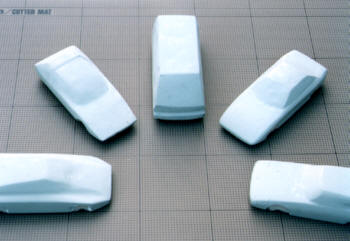

The original material is light board.

Stick thick light board and start to cut biggish than outside size.

It is like Bird Curving.

It is the best to cut the state of covering seat cover.

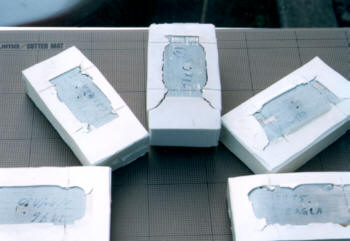

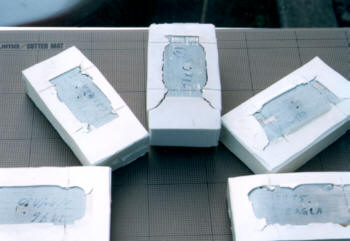

For preparing for modeling by silicon beforehand, fill up froth of light

board.

Not to sink silicon into it.

Make an outline by handcraft paper and pour silicon into it.

At past time, there was no evacuating and getting rid of froth machine,

I used silicon I could buy in model shop.

I didnft notice about shrinking rate, it was true I only thing of changing

for resin.

At the present time, I make that nature use of making, so I made it little

bit bigger.

I can get to choose shrinking rate and not shrinking rate.

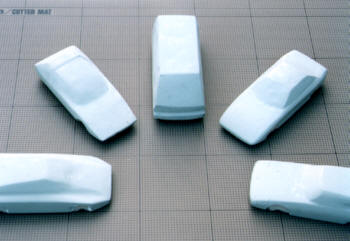

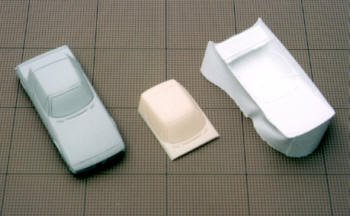

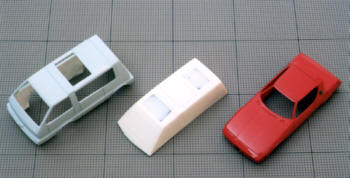

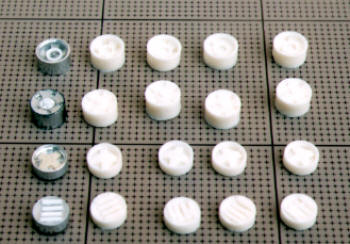

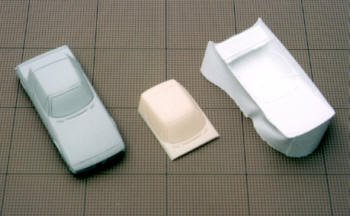

The two models of left are made from light board and the right is made

from resin.

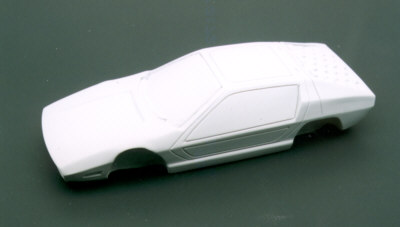

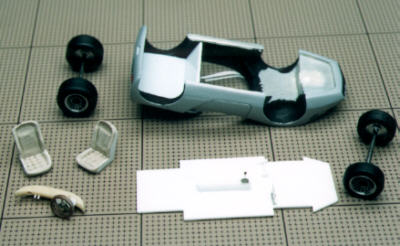

I used resin body for prototype.

At this time, for to decide standard of groove, flatten the lower part.

At present time, it is easy because MODELA and endmill shave a standard

side.

The good thing of digital data is making right and left sides as turning

over.

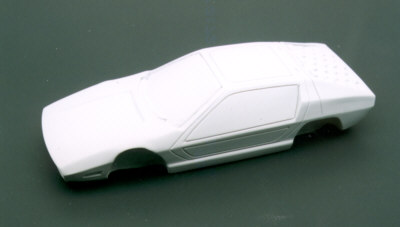

With seeing resinous skin, revise warp of the body of a car.

Human eyes are random, so it looks good for me.

This was the most difficult at that time.

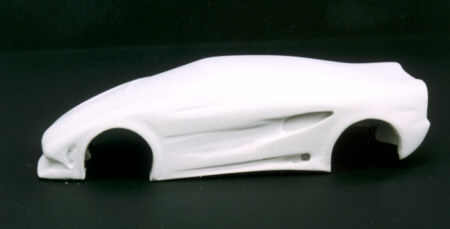

At present time, I only rub and put together accumulations named of kmical

wood.

Make it shapes of image with a tool by electricity and a rasp.

Using back-ground paint stretches its surface, not to mind about a inner

curved surface.

Make each parts with plastic board and epokici pute.

Make it up with thinking about drawing.

This section is the same with a present time, although, I donft use poliestel

pute( A cause of not to stiffen) to make a master with thinking about casting

silicon many times.

At past time, there are many cars styled boxy.

It was possible to make be look like with getting a charm point of the

car.

In the trade of real cars artists made with their hands, so it was good

to make model car.

But the present show-models became complicated shapes because of making

by CAD.

It is impossible to make with epokici pute and plustic board.

These three curved sides and curved lines of plural value is on modelerfs

endmill.

Handmade car is made the best by hand making.@A car made by CAD is made

the best by CAD making.

Is it of course???

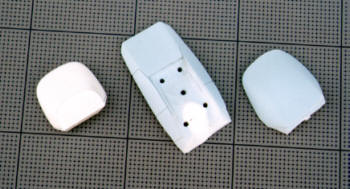

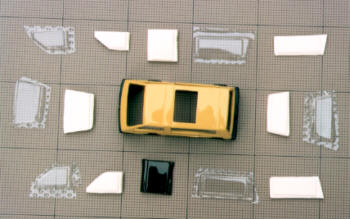

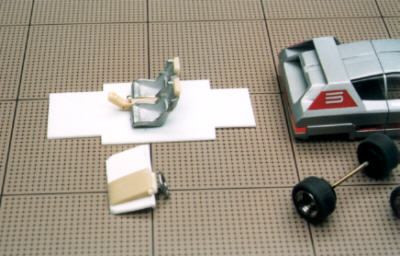

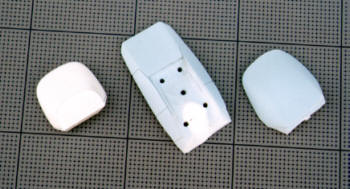

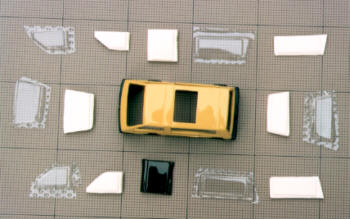

The progress of making parts of windows is modeling windows of body which

became a master by silicon.

gThe picture of lefth

Pour resin into it and make a copy of parts of windows.

gThe picture of righth

Cut the parts of windows for body.

A pattern of windows are for a pattern for vacuum.

gThe picture of righth

At present time, take clearance thinking about thick of vinyl chloride

sheet and adjust.

Now, it is the progress of making windows.

Shave parts of windows with motore tool.

At past time, I used cheep Ploxsonfs.

It singed an axis immediately and not turned round quickly, sometimes an

edge bitted resin so I got hurt many times.

At present time, I use a firm one made in JapangClesticEPouerCrester

PC33Ch.

It turns round 30.000rpm, itfs a magical pencil.

The edge of blade is a super hard cutter, so it is great to shave.

I recommend this.

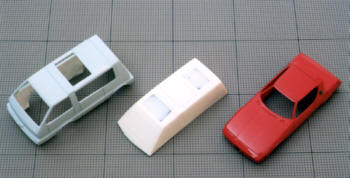

Vacuum vinyl chloride seet with adjusting each car. This is using smoked

vinyl chloride seet.

Use clear 0.2mm-0.5mm thick board for each part.

The car of right has seven windows, so itfs impossible to do it at once,

and then divide to do it.

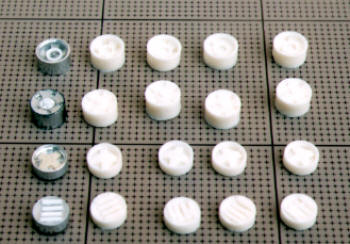

Now, it is the progress of making wheels of tire.

Make it with wheels sold by each parts manufactures.

Choose wheels with comparing body and seeing clearance, and choose flat

rate and long with comparing balance.

For show-model there are almost only one, so you have to make it.

A rim of a wheel is made with aluminum and inner parts are made by combination

of each material.

These are a master, and make wheels for one car.

At past time, I didnft know to draw on resin, so I worked hard.

At present time, I can reproduce them without be worried about froth.

At last the pattern of making wheel uses the minimum chisel gSharpen a

screwdriver for watchh.

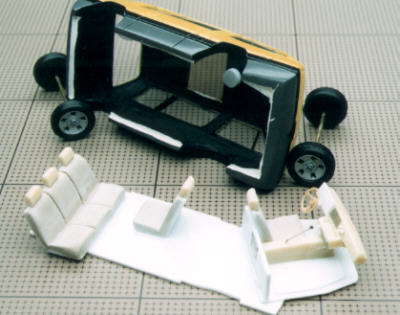

Well, body and windows are done. Detailed parts are also done.

These works are not change now and before.

The picture of the side of rear.

A tail lamp cut from vinyl chloride seet and uses cutting seat.

This is what wheels of tire fitted temporary.

The interior is not inconspicuous, so make it selectively for an atmosphere.

Materials are plastic board, plastic stick, a piece of resin, and epokisi

pute.

It looks good little bit smaller than looking.

At present time I make it this way, after making these many things, I can

get the point.

Find an accent of that car, and have designerfs mind.

It looks good with putting emphasis on there.

It is the same with drawing pictures.

It is over. So letfs make models!